Acroview shines at NEPCON CHINA 2025, setting a new benchmark for chip programming and testing.

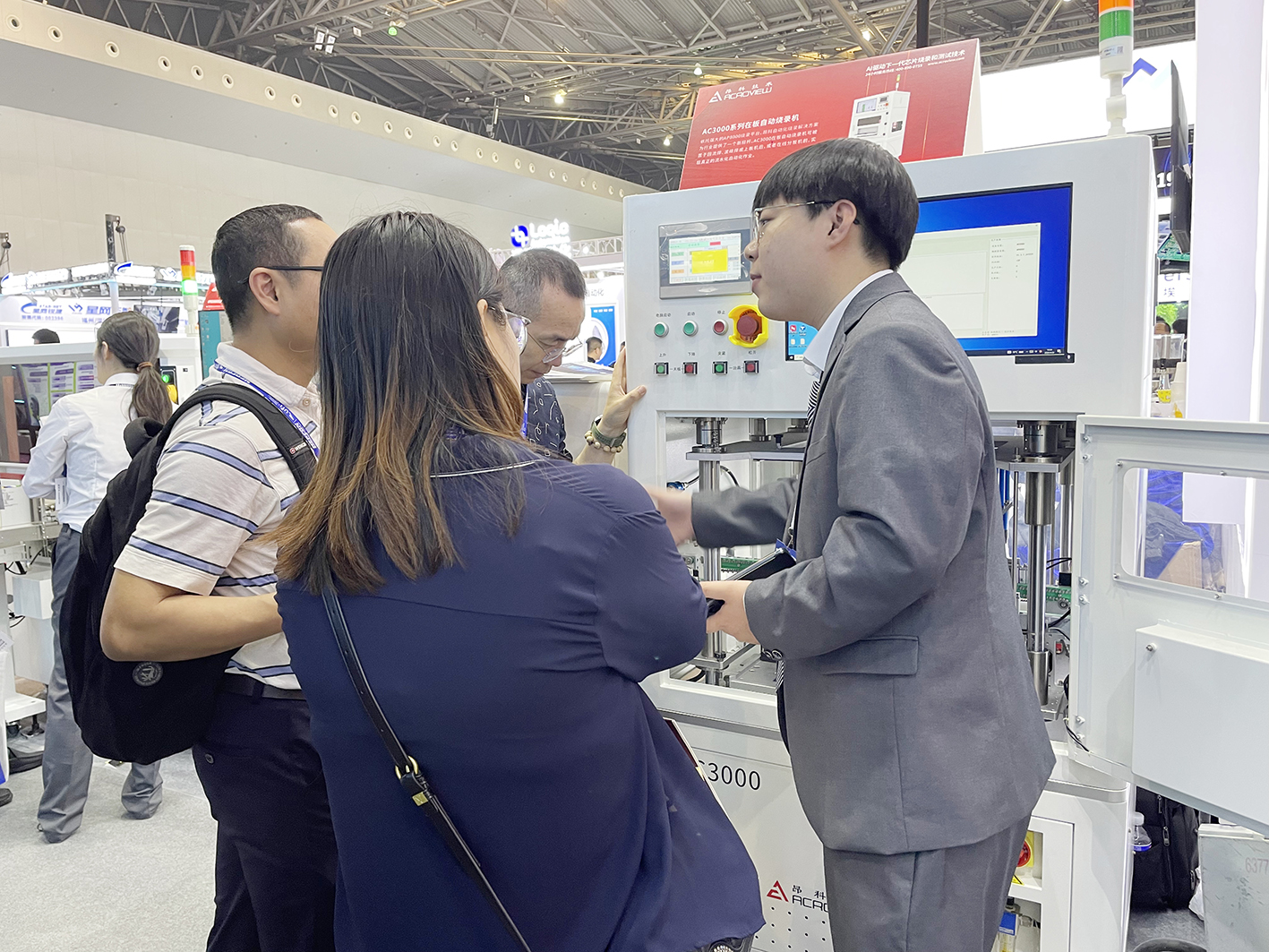

From April 22nd to 24th, the 33rd China International Electronics Manufacturing Equipment and Microelectronics Industry Exhibition (NEPCON China 2025) successfully concluded at the Shanghai World Expo Exhibition & Convention Center. As a premier annual event for the global electronics manufacturing industry, Acroview Technology showcased its leading capabilities in semiconductor back-end processes at booth 1B35 in Hall 1, demonstrating its dual-engine technology matrix of "chip programming + testing," becoming one of the most watched highlights of the exhibition.

At the exhibition, Acroview's chip programming and testing equipment, including AP8000, IPS5800S, AC3000 , MS-700, and V9000, made a splendid appearance . Acroview's engineers provided enthusiastic and professional on-site explanations and offered highly targeted customized solutions for different customer needs.

The AP8000 universal programmer showcased at this exhibition is an independently developed universal programmer platform by Acroview Technology. It not only supports programming almost all programmable chips on the market, but also serves as the core programming platform for automated programmers, a key device for achieving stable and reliable mass production of program code for chips. The AP8000 can meet the diverse and complex application needs of customers, from small-batch manual programming and fully automated offline die programming to fully automated on-board programming. It also supports various programmable devices such as Nor/Nand Flash, eMMC, UFS, MCU, FPGA, and CPLD. Currently, Acroview Technology has successfully developed and supported tens of thousands of different semiconductor components from domestic and international manufacturers.

The IPS5800S fully automatic chip programmer was undoubtedly the star product at the exhibition. Its efficient and stable operation attracted numerous customers to stop and exchange ideas. The IPS5800S adopts a newly designed four-nozzle chip pick-and-place system, achieving high-speed, high-efficiency (UPH3500) operation while maintaining pick-and-place accuracy and ultra-quiet operation. The perfect combination of a high-performance servo drive system and a high-precision ball screw transmission system achieves an organic combination of ultra-high precision and ultra-high output efficiency. This system supports the programming of various ultra-small package sizes and can be integrated with MES (Manufacturing Execution System) to ensure full control and traceability of the production process, providing customers with more reliable and efficient production assurance.

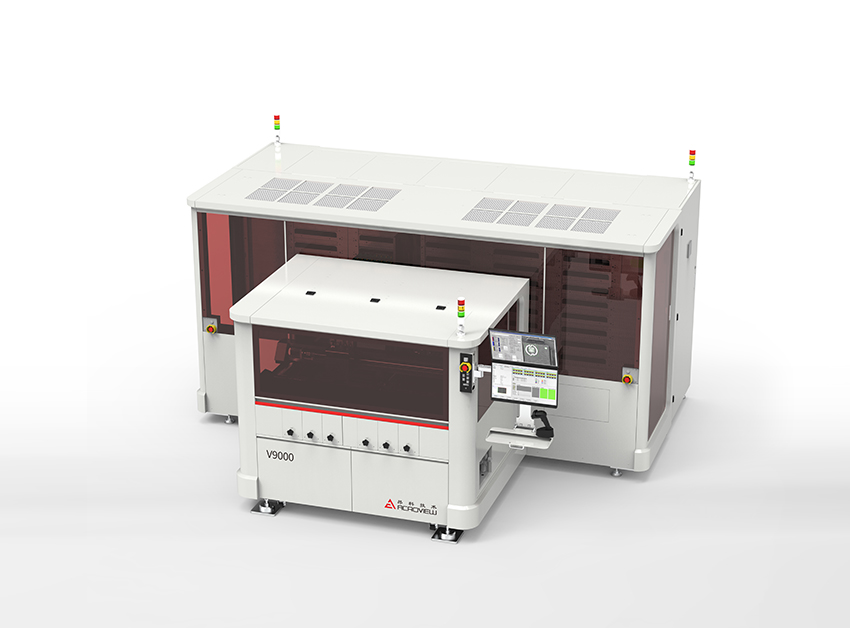

Acroview Technology's V9000 series test sorters also became a focal point. Designed for high-reliability testing needs, this series can be widely used for system-level testing of power modules, AI training chips (SOC/GPU/CPU), autonomous driving chips, and various memory chips (eMMC/UFS/LPDDR). The V9000-BI series, in particular, features innovative optimizations for AI chip testing. Its groundbreaking fully automated BI testing solution not only increases the single DUT testing power to an industry-leading 1500W (a 50% increase over existing levels), but also effectively solves the inefficiencies and quality control challenges of traditional multi-station testing through an integrated testing architecture. This innovation provides a completely new solution for the reliability testing of high-power-density semiconductor products such as AI chips.

To address chip marking needs, Acroview Technology's MS-700 laser marking machine is equipped with its independently developed LaserExtreme™ control system, which enables intelligent marking path optimization and precise positioning. It can meet the marking needs of various product forms such as trays, thin film frames, and wafers, providing customers with efficient and reliable marking solutions.

As a chip programming and testing equipment expert serving leading companies such as Huawei, Infineon, and BYD, Acroview Technology is committed to technological innovation. In emerging fields such as AI computing and automotive electronics, Acroview's chip programming and testing solutions are driving the improvement of industry technical standards.

Mr. Fu Guo, Vice President of Acroview Technology, gave several exclusive interviews to various media outlets, showcasing Acroview's latest R&D achievements and innovative technologies in the fields of programming and testing, further enhancing Acroview's brand awareness and industry influence. Acroview's advanced products and solutions received high praise and recognition from industry experts and the media, giving the company a greater advantage in future fierce market competition.

The conclusion of NEPCON CHINA 2025 marks a new era of intelligent and green development for the electronics manufacturing industry. Acroview Technology, driven by a dual approach of "technology + ecosystem," not only showcased the innovative strength of Chinese semiconductor equipment companies but also redefined industry standards for chip programming and testing with a global perspective. In the future, with its deep involvement in fields such as AI and automotive electronics, this Chinese company is expected to play an even more significant role in the global semiconductor supply chain.

- Previous: NEPCON Shanghai Event – Highlights of Acroview Chip Testing and Burning Revealed

- Next: No More!