-

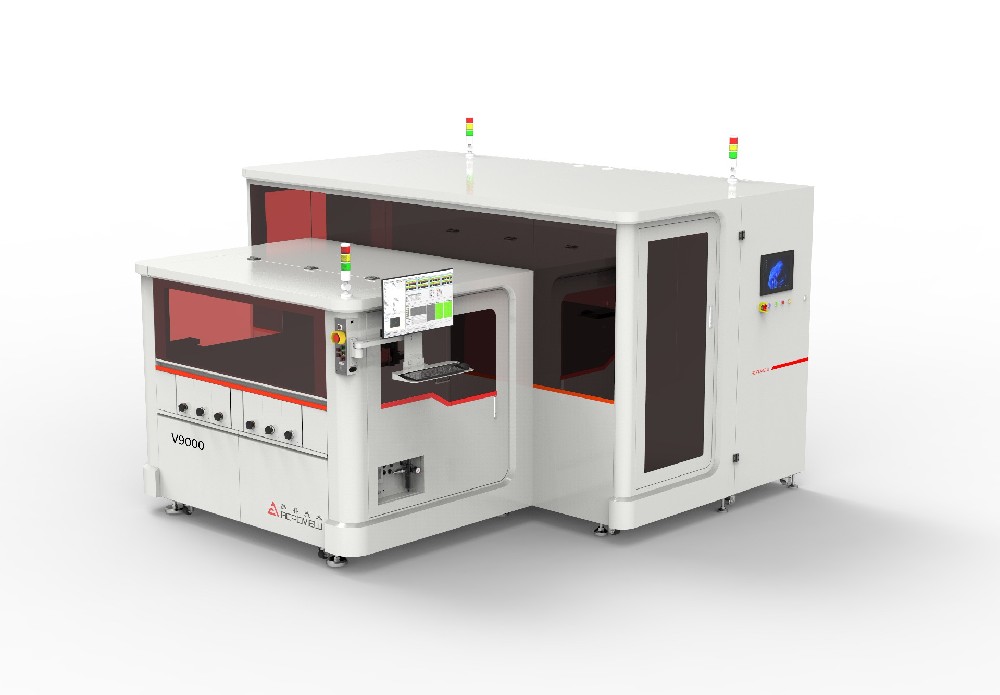

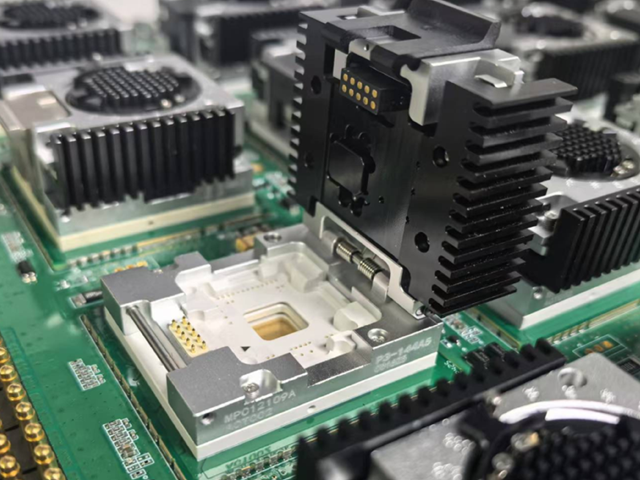

Applied to the burn-in testing of high-power power modules/chips for AI servers.

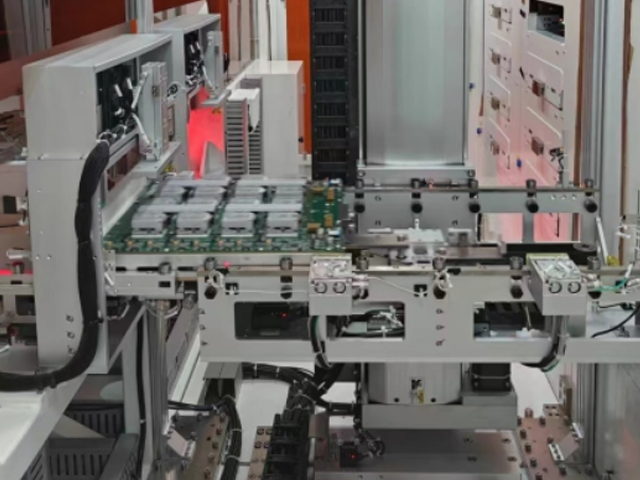

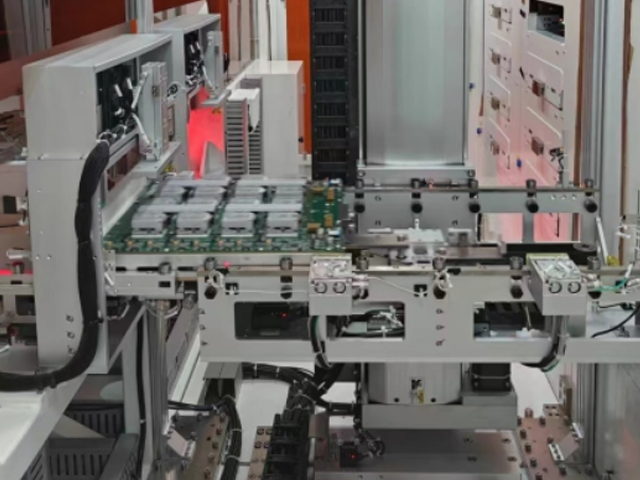

Comprehensive BIB-integrated testing capabilities, facilitating easier maintenance, socket replacement, and disassembly/assembly.

Precise independent temperature control design based on junction temperature (Tj) control provides excellent temperature precision and uniformity for target DUTs.

Fully automated monitoring, recording, and analysis of all Burn-In test data, enabling clear and immediate data analysis and diagnostics.

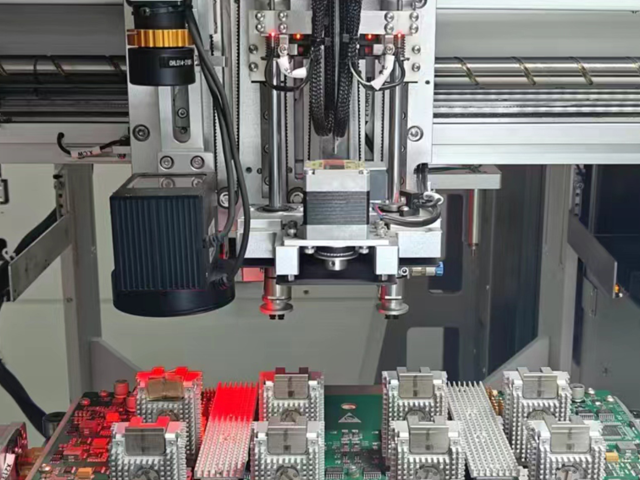

World's first stackable ABI testing technology—always imitated, never surpassed!

Full-process ESD control during testing ensures DUT quality.

High-precision visual inspection (3D5S, appearance defect detection, QR code recognition, etc.) ensures testing quality.

Energy-recovering load with up to 90% efficiency, saving energy and being environmentally friendly.

Full-stack in-house R&D (embedded software, FPGA, hardware, motion control, electrical, mechanical, thermal design, etc.) enables a fast and responsive service system.

Incorporates AI large models to enable intelligent IC testing.

In 2021, acquired a renowned Japanese handler company with 40 years of precision engineering heritage, offering exquisite product technology and an ultra-low Jam Rate.

Feature functions World's first ABI fully automated burn-in testing

World's first ABI fully automated burn-in testing Supports ultra-high-power DUTs exceeding 600W

Supports ultra-high-power DUTs exceeding 600W Ultra-high parallel test count, three times that of similar products on the market

Ultra-high parallel test count, three times that of similar products on the market Independent temperature control design provides excellent temperature precision and uniformity for target DUTs

Independent temperature control design provides excellent temperature precision and uniformity for target DUTs Full-channel regenerative electronic load enables full-load pulling

Full-channel regenerative electronic load enables full-load pulling High-precision visual AOI inspection ensures testing quality

High-precision visual AOI inspection ensures testing quality -

Supported Device Types QFN, QFP, LGA, PLCC, PGA, CSP, TSOP, etc. Device Size Range From 3x3 mm to 100x100 mm Operation Mode Normal Mode, Practice Mode, Dry-Run Mode Control System Industrial Computer Operating System WINDOWS MTBA > 4 Hours UPH UPH ≥ 1000 Down Time < 3% (when running continuously for 3 months) Index Time < 0.4s (Minimum: 0.38s) Jam Rate ≤ 1/5000 Temperature Control Range Room Temperature to 125°C (DUT temperature can reach up to 150°C) Tray Standard JEDEC Standard Tray Loading/Unloading Mechanism 1x Automatic Loader / 4x Automatic Unloaders (Expandable) Empty Tray Handling Gripper Type Software Binning Bin1 - Bin16 Power Supply Specification 50/60 Hz, Max. 50A, AC 380V (Three-Phase) Machine Weight 3500 kg Machine Dimensions (L x W x H) 3189 x 3400 x 1920 mm