-

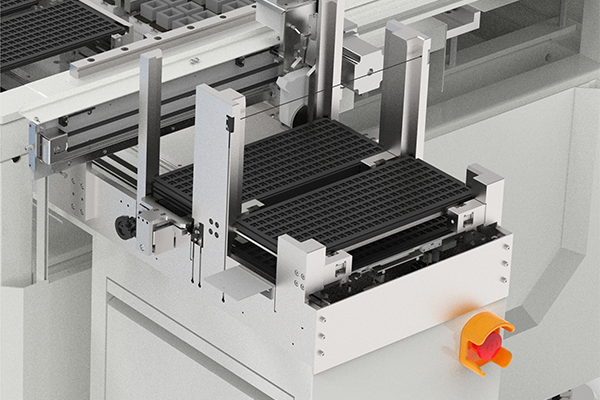

The IPS5800S is a four-nozzle, high-performance automated programming machine introduced by Acroview. It can be equipped with up to 8 powerful Acroview programming cores (AP8000), and the system can be expanded to a maximum of 64 or 128 programming stations, providing customers with efficient and cost-effective production capacity utilization.

Built upon Acroview's widely trusted IPS automation platform architecture, ensuring stable and reliable operation throughout the entire machine lifecycle.

The newly designed four-nozzle chip handling system achieves high speed and efficiency (UPH 3500) while maintaining excellent placement accuracy and ultra-quiet operation.

A high-performance servo drive system combined with a high-precision ball screw transmission system achieves the perfect integration of ultra-high precision and ultra-high throughput.

The system supports programming of various extremely small form-factor packages.

Integration with MES (Manufacturing Execution System) enables full-process control and traceability of production.

Feature functions High-Throughput Universal Programmer AP8000Built-in 8 programmers, 64 or 128 programming stations

High-Throughput Universal Programmer AP8000Built-in 8 programmers, 64 or 128 programming stations

Up to 3500 UPH (Units Per Hour)

Supported IC types: UFS, eMMC, MCU, Nor/Nand Flash, EEPROM, CPLD, FPGA, Anti-Fuse, and other customer-customized chips/modules

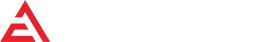

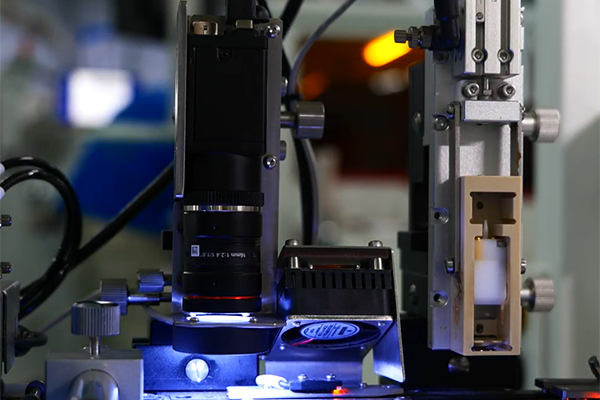

Comprehensive support for various IC package forms Intelligent Vision SystemFour lower cameras (1.3MP) for synchronous IC alignment correction; one upper camera (1.3MP) for positioning at various workstations (including trays, tape-and-reel programming sockets, etc.)

Intelligent Vision SystemFour lower cameras (1.3MP) for synchronous IC alignment correction; one upper camera (1.3MP) for positioning at various workstations (including trays, tape-and-reel programming sockets, etc.)

Fully automatic IC contour recognition and positioning, eliminating traditional template matching for easier operation

High-precision recognition of极小 chips, supporting 1.0x1.5mm chip packages

More precise IC pick & place, ensuring chip handling stability and high throughput High Throughput & High ReliabilityFour-nozzle high-precision IC Pick&Place module

High Throughput & High ReliabilityFour-nozzle high-precision IC Pick&Place module

UPH 3500

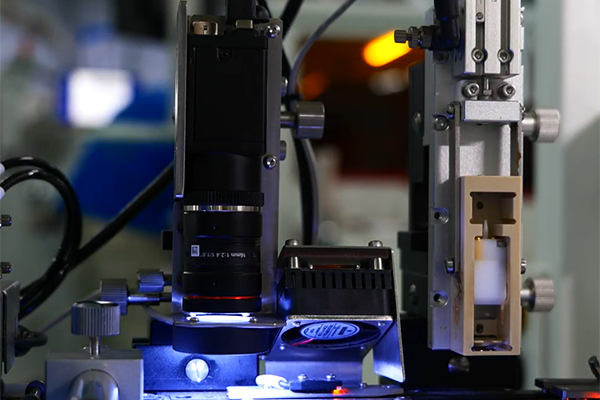

Automated real-time stack detection Auto Tray Handling SystemEfficient automatic tray system; loading/unloading does not affect UPH

Auto Tray Handling SystemEfficient automatic tray system; loading/unloading does not affect UPH

Simple and reliable automatic tray system enhances overall system stability Automatic Tape-and-Reel Out (Tape Out) EquipmentSimultaneously supports both cold and hot seal packaging

Automatic Tape-and-Reel Out (Tape Out) EquipmentSimultaneously supports both cold and hot seal packaging

Supports 8~44mm tape width, expandable to 72mm

High-precision stepping feed (+/-0.04mm) Vision Inspection ModuleImproves the completeness of chips in tape-and-reel output

Vision Inspection ModuleImproves the completeness of chips in tape-and-reel output

Effectively identifies defects such as flipped chips, reversed orientation, missing marks, etc.

Can simultaneously inspect 2 features, e.g., polarity dot and silk screen Automatic Tube Feeder EquipmentSingle-track independent channel; tracks can be replaced according to IC specifications

Automatic Tube Feeder EquipmentSingle-track independent channel; tracks can be replaced according to IC specifications

Front-end belt conveying for greater stability

Up to 40 IC tubes can be loaded for 4mm raw material tubes Ink Dotting Mechanism, Inkjet Printer, and Laser MarkingOptional ink dotting mechanism supports marking for auto-tray and auto-tape-and-reel output ICs

Ink Dotting Mechanism, Inkjet Printer, and Laser MarkingOptional ink dotting mechanism supports marking for auto-tray and auto-tape-and-reel output ICs

Optional inkjet printing supports marking for auto-tray and auto-tape-and-reel output ICs

✔ Supports dotting and character printing ✔ Supports multiple colors ✔ Ink complies with ROHS requirements

Optional laser marking supports marking for auto-tray and auto-tape-and-reel output ICs

✔ Supports printing various characters ✔ Supports printing QR codes