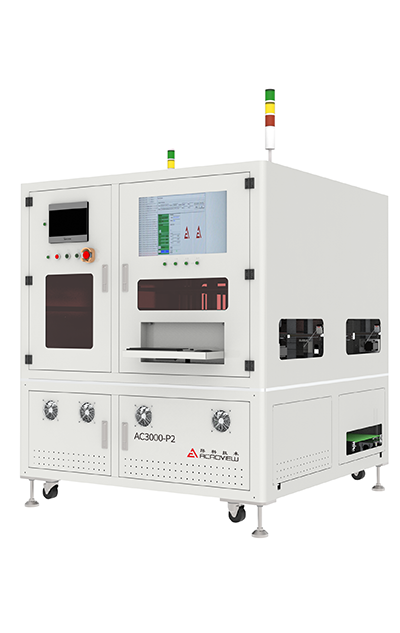

In-circuit programming primarily addresses high-volume production, supporting multiple programs for the same chip model. By connecting to the MES system, it saves complete programming data records, ensuring process traceability.

Via Ethernet interface, it can connect to multiple AP8000 units, enabling simultaneous/asynchronous programming for over 128+ connected boards.

Equipped with a barcode scanner to automatically match programming files based on product barcodes.

Removable needle bed enables rapid line changeover (changeover time < 10 minutes).

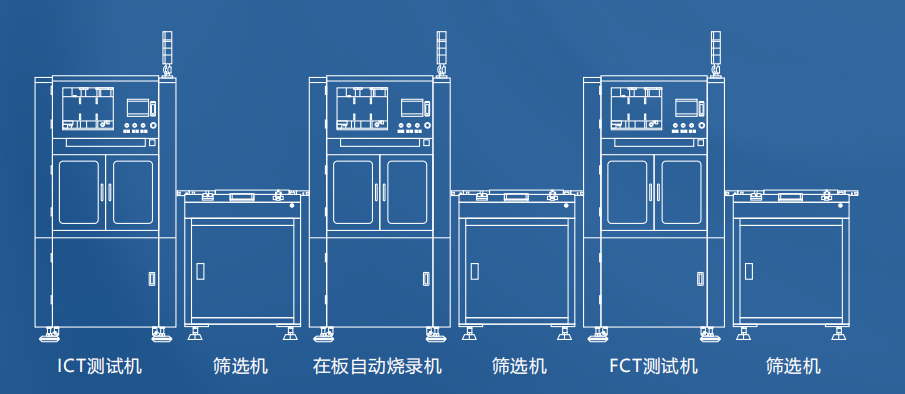

Utilizes the European-standard SMEMA interface for easy connection to upstream and downstream automated production line equipment.

Defective product alarm function; if integrated with an inline board separator, it can automatically separate defective boards.

Features error-proofing functions to prevent misplacement or incorrect board orientation, reducing losses.